2016 celebrates the 25th anniversary of MS Powder Systems as an innovative global leader in powder coatings equipment technology. MS Powder Systems is based in Balgach, Switzerland, considered by many as the world’s Powder Valley.

2016 celebrates the 25th anniversary of MS Powder Systems as an innovative global leader in powder coatings equipment technology. MS Powder Systems is based in Balgach, Switzerland, considered by many as the world’s Powder Valley.

History

MS Powder Systems was founded in 1991 by Henry Marcon and remained in the Marcon family ownership until the company was acquired in early 2016 by Carlisle Fluid Technologies. Since its foundation, the company has steadily grown and developed into a leading manufacturer and installer of powder coating and booth systems. MS moved into its purpose built factory and offices at Balgach, Switzerland in 1999 and now has representation in Germany, France, Italy, Austria and Portugal as well as in Russia and the United States. Joining forces with Carlisle means that MS will be able to expand its market to reach customers in every corner of the world.

MS

We have been developing over the past twenty-five years to become a leading manufacturer of powder coating systems.

Our systems are sold, installed and maintained worldwide through our distribution network. The entire development, planning and production of our tailor-made equipment is customized to the needs of our customers and take place at our headquarters in Balgach, Switzerland.

Your system is precisely designed using the latest 3D CAD systems, thus allowing advance assessment in terms of connectivity and spatial requirements. Being consistently on the lookout for high-quality and innovative applications, we were able to successfully gain ground among the powder coating system suppliers in various fields of application in recent years

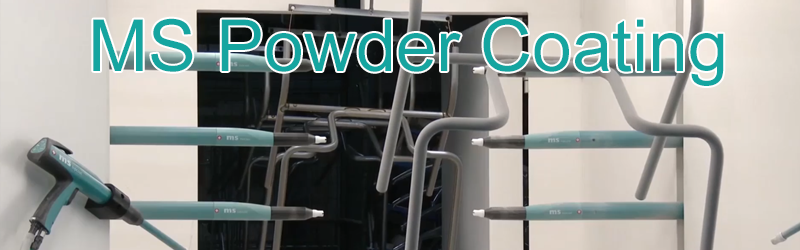

MS topcoat M4 / MS topcoater speedy

The light weight, ergonomic design of the MS topcoat M4 helps to keep operator fatigue to a minimum. The perfect balance means that the gun sits comfortably in the hand, minimising physical strain and the light pull trigger can be operated with one or two fingers.

State-of-the art digital control and advanced gun technology improves transfer efficiency, surface finish and powder consumption.

MS topcoat A4 / Reciprocators

MS topcoat series 4 represents the forefront of powder application technology. Our newest range includes an advanced automatic powder gun and the lightest manual gun in its class.

As well as being very easy to use, MS topcoat series 4 products offer outstanding powder charging and high transfer efficiency.

MS Reciprocators

These electronically controlled reciprocators with X-Y and Z axes have been developed for efficient production operation in automated powder coating systems.

This sophisticated system can be expanded thanks to its modular design - with a control module for a lifting machine all the way to complex axis control systems using PC controllers.

Tailor-made systems

More and more customers are looking for partners with high service competence to cooperate in the long term in the field of powder coating.

Individual and customized concept solutions are gaining more significance. MS Oberflächentechnik AG meets these requirements.

Since its founding in 1991, the company along with its staff has focused on the development of innovation. It develops and manufactures customized fast-color-change powder coating systems, based on state-of-the-art and economically feasible technologies, in partnership with its customers.

These are designed for vertical and for horizontal coating, depending on the requirements.

The powder coating of MDF surfaces is considerably more demanding, especially in terms of the gelation and curing of the powder in the furnace. We offer complete MDF systems, including feed and furnace - thanks to our integrated know-how.

The step to automation

Only when all systems are perfectly tuned to one another and when they function properly, the transit rate can actually be increased. We shall explain to you in detailed consultation sessions as to whether a full automation makes sense or whether only individual working steps should be automated.

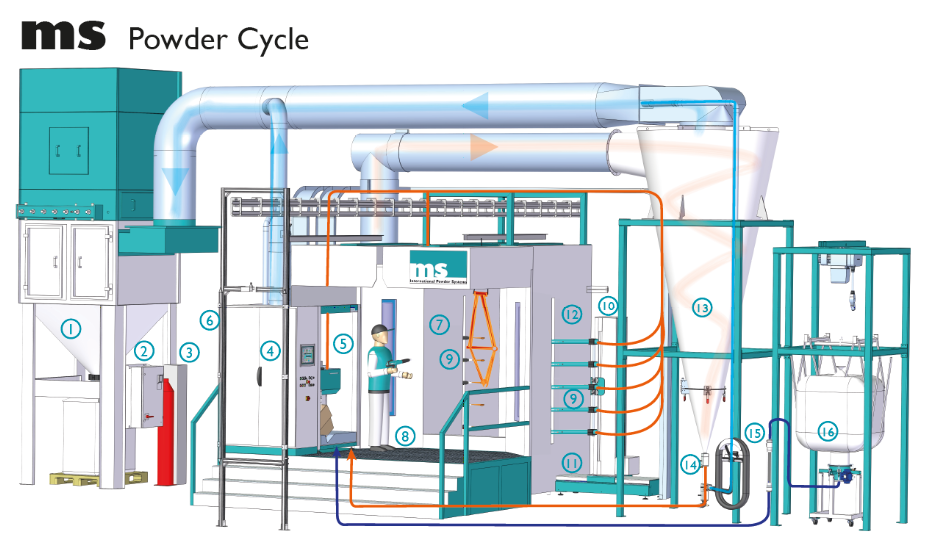

Powder booth system

The increasing colour and product diversity and smaller production batches at the same time requires more and more flexibility in the powder coating business. The MS powder coating conceptions are optimally customized. This leads to a much better cost-benefit ratio and payoff.

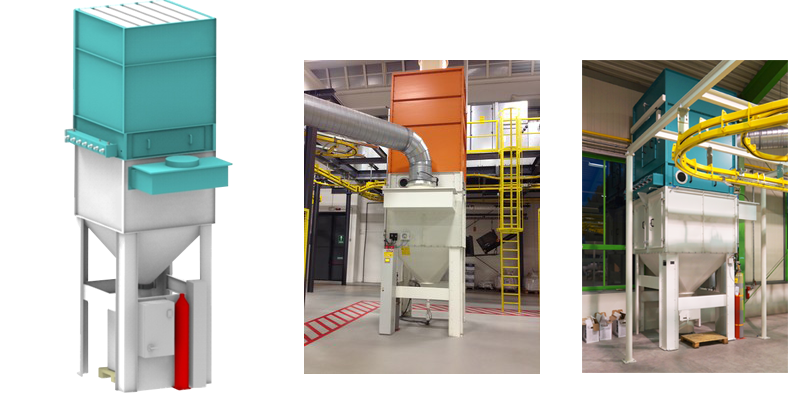

- MS Powder Filter

- MS Controller with Frequency Changer

- Fire Suppressor System

- MS Controller with Touch Panel

- MS Powder Center

- MS Part Detection

- MS FCO Fast Color Change Booth

- MS Pre Coating

- MS Corona topcoat gun A4

- MS Reciprocator

- MS Sliding Table

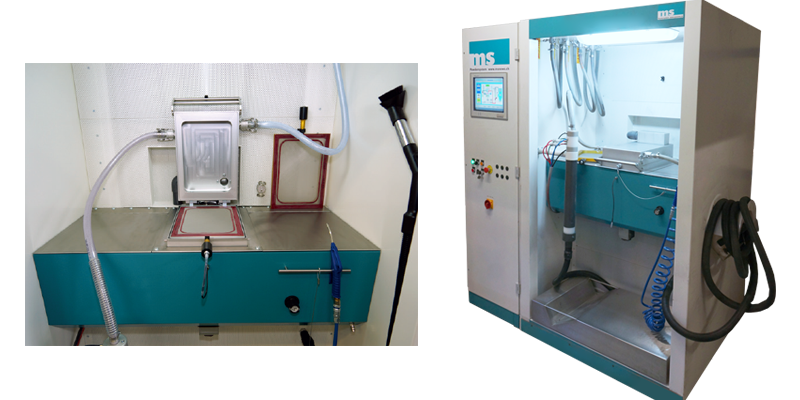

- MS Gun Cleaning

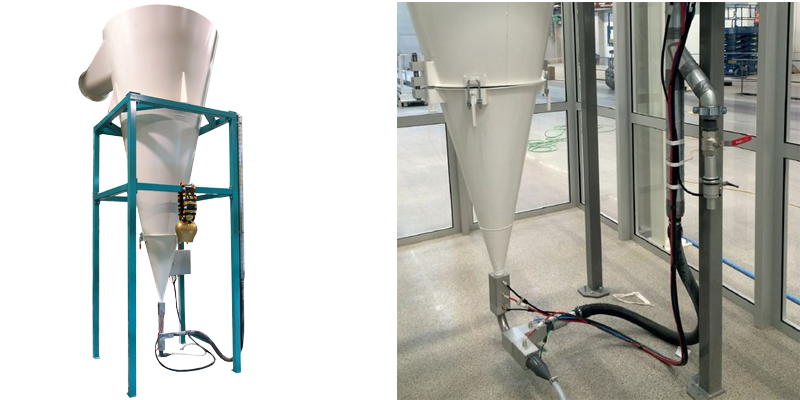

- MS Cyclone

- MS Powder Recovery

- MS Powder Pump

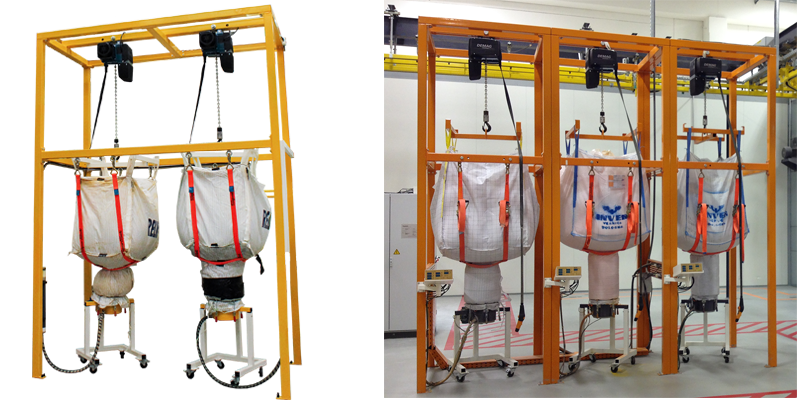

- MS Big Bag

Powder Coating Laboratory (Yokohama)

MS Components

-

MS Powder Kitchen PKV24

Of crucial importance for economical powder coating with many color changes is a powder kitchen with automated powder supply from the original powder container.

-

MS Jet-Clean Absolute Filter

MS Jetclean series of technology provides powder material separation from the in-coming air stream mixture.

-

MS Big Bag Powder Feed Supply System

Powder equipment users might benefit from the convenience of purchasing and handling powder materials in bulk using Big Bag, or sack technology.

-

MS Cyclone Powder Recovery Units

The MS cyclone design is optimized for the highest efficiency in powder reclaim, ensuring contamination free powder coating operation.