RANS-COSMOS

The First Fully Automatic Coating System in the World "RANS-COSMOS"

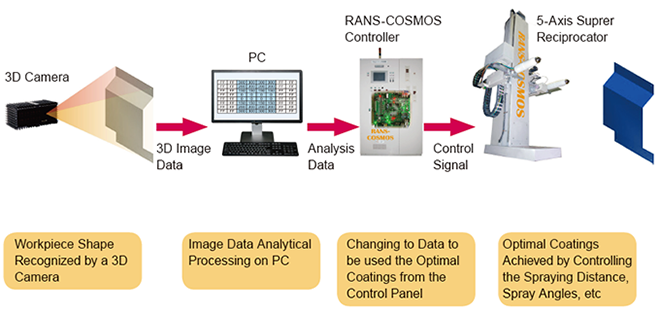

Work Shape Recognition and 3D Data Processing

The size and shape of the workpiece are detected as three-dimensional image by a 3D infrared camera installed at the entrance of the paint booth and the detected image will be converted to numerical data on PC.

Analyzing Coating Conditions, Central Control System for Various Equipment

The numerical data is converted by the CPU equipped RANS-COSMOS Control Panel to control data in order to perform the optimum coating, and output to coating data which is used to control devices including super reciprocator, coating equipment and the paint supply device.

Super Reciprocator Equipped with Devices that Move Back and Forth, Ultracompact Paint Supply Equipment also May Be Added.

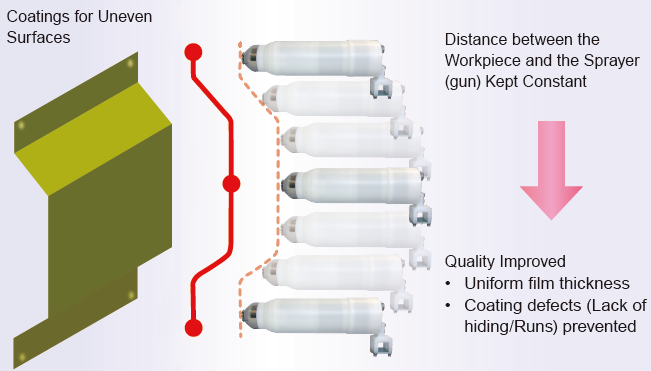

Devices that move back and forth to keep the distance are equipped separately with the right and left arms of the reciprocator so that the shape of the workpiece can be correctly traced and thus make stable coating possible.

Variable-stoke and smooth reciprocator response are available due to the counter weight structure and AC servo motor. Besides, the ultra-compact paint supply equipment (CCV/FGP) can be configured directly on the arm, so the color change time and paints/thinner consumption are minimized.

RANS-COSMOS Flow of the Fully Automatic Coating

Features

- 3D Camera

Designed with a near-infrared LED used high speed light source and a special CMOS image sensor which senses the bouncing back of light, the camera measures the spraying distance and the shape of the workpiece to output the image data in real time.

If the shape of the workpiece is too complex, correct image recognition can be acquired by synthesizing the image data from multiple 3D cameras used. The image data will be converted to 3D numerical data on PC. - RANS-COSMOS Control Unit

With the CPU equipped RANS-COSMOS Control Unit, the 3D numerical data is changed to control data used for coating equipment to achieve the optimum coatings.

Main Control Features:- Back and forth movement control to keep the spraying distance constant

- Paint supply control to turn “ON”/“OFF” according to the shape of the workpiece (Recognizes both the external shape and hollow structure.)

- Appropriate amount of overspray control

- Super Reciprocator stroke width control

- Delivery control depending on the variable stroke

- Electrostatic Coating Equipment (Micro Bell / RAgent Gun)

(Micro Bell)

Controls the shaping air according to the shape of the workpiece. The optimum coatings are achieved by using the adjustable pattern bell.

(RAgent Gun)

Controlling the spray pattern by changing the atomizing air or pattern air makes the optimum coatings possible. - Super Reciprocator

Equipped with a device that moves back and forth, the super reciprocator has the following features:- Equipped with a device that moves the sprayer back and forth to keep the spraying distance constant.

- The device that moves back and forth is separated into right and left. Each of the coating equipment installed with each side of the reciprocator is independent and keeps the optimum spraying distance constant.

- The ultra-compact paint supply equipment (CCV/FGP) can be installed directly with this reciprocator to reduce the color change time and paint consumption. Even for the heavy arms due to the added sprayer or paint supply equipment, smooth operations and high response are available due to the counter weight structure and the forward/reverse function of the AC servo motor.

- Paint Supply Equipment (CCV/FGP)

The ultra-compact flushable gear pump (FGP) and color change valve (CCV) are newly developed in order to be installed directly with the super reciprocator. By shortening the distance between the sprayer and the paint supply to a minimum, the color change time and thinner consumption are reduced, which leads to improved efficiency and lower costs.

RANS-COSMOS Example

RANS-COSMOS's Development Possibilities

- Recognizing the shape of the workpiece automatically, the RANS-COSMOS system can select the optimum coating conditions from an enormous quantity of data storage or test data accumulated before and apply to coatings immediately.

- Differences between the workpiece and the hangers are detected to avoid coating for unnecessary parts, so the missing ground due to the coating for hangers can be prevented (electrostatic coating safety improved). As the result, paint consumption and cleaning frequency are reduced.

- The image data recognized by the RANS-COSMOS system is transferred to the robot coating system to be applied to the automatic calls from the robot operating program or from the coating conditions.

- The work shape recognition function makes the productivity and paint consumption clear and easy to understand, so advanced management is made possible.

- Possibilities, for example, the optimum coating conditions were automatically set by feeding back the temperature and humidity control data on site to the RANS-COSMOS system, are highly expected.

- If the film thickness would be detected automatically, higher coating performance and more paint consumption reduction could be achieved by feeding back the detected data to the RANS-COSMOS system.